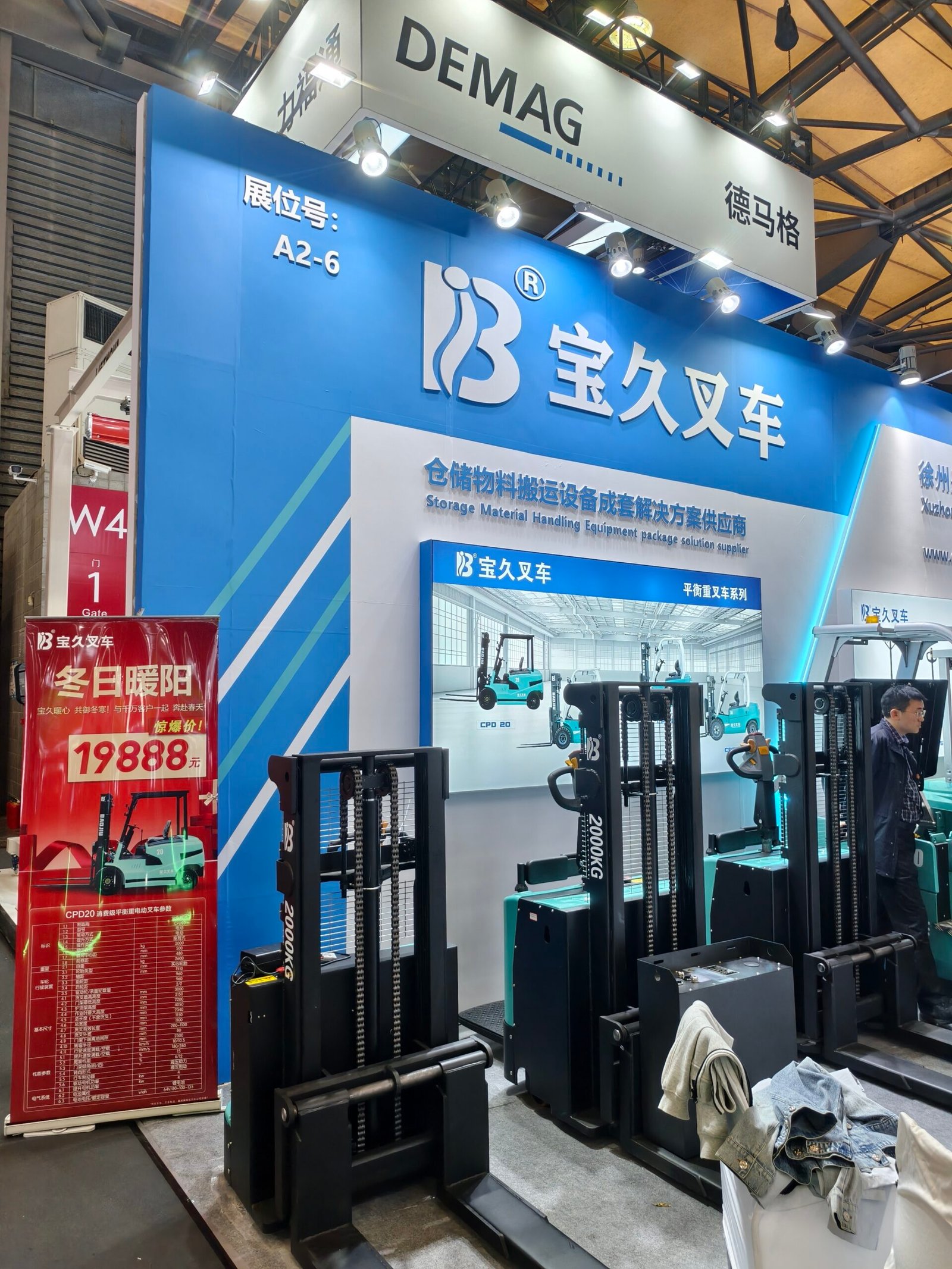

In the dynamic material handling sector, every operation has unique needs. Off-the-shelf electric forklifts often fail to match requirements like narrow aisle navigation, irregular load lifting, or harsh environment operation. At our factory, we recognize customization is critical for boosting productivity, safety, and efficiency. Can we tailor forklifts to your specific needs—such as attachments and special dimensions? The answer is a resounding yes.

Customized Attachments: Beyond Standard Forks

Standard forks suit general lifting, but many industries need specialized tools. We offer a full range of custom attachments, engineered to integrate seamlessly with our electric forklifts for your unique tasks.

Whether you need clamps for paper/textile pallets, side-shifters for precision, rotators for load inversion, or fork extensions for long materials, our engineers collaborate with you to create attachments meeting exact specs. We also cater to niche needs like custom lift beams for heavy/awkward loads or telescopic forks for high-density storage. Each attachment undergoes strict testing for compatibility, durability, and safety.

Special Dimensions: Adapting to Space Constraints & Load Requirements

Space limits, unique layouts, and specific load sizes often require non-standard forklift dimensions. Our factory can modify key design aspects, from compact models for narrow aisles to reinforced units for heavy-duty tasks.

For confined spaces (small warehouses, shipping containers), we adjust width, height, and turning radius—including low-profile models for low ceilings. For heavy loads or high racks, we engineer extended wheelbases, reinforced frames, or custom mast heights. We also optimize seat positions and controls for operator comfort.

The Customization Process: Collaborative & Results-Driven

Our customization process is collaborative. We first understand your operational challenges, load traits, and safety needs. Our engineers analyze and develop tailored solutions, sharing designs for approval and keeping you updated throughout production.

We prioritize sustainability in custom designs. Our zero-emission electric forklifts are eco-friendly, and customizations preserve these benefits—e.g., energy-efficient attachments and space-optimized dimensions.

Why Choose Our Custom Electric Forklifts?

Partnering with us means getting a business-specific solution, not just a modified machine. Our advanced facilities, experienced engineers, and quality commitment ensure top performance and reliability.

We also provide ongoing support—maintenance and custom spare parts—to keep your forklift efficient. Whether you’re a small niche business or a large enterprise, we deliver solutions for complex needs.

Final Thoughts

Operational flexibility drives success. Off-the-shelf solutions fall short, but custom electric forklifts transform material handling. We build not just forklifts, but perfect-fit business solutions.

Ready to elevate your operations? Contact our team today to design a custom electric forklift tailored to your needs.